Job Archives

- Assembling, installing, and maintaining mechanical systems, machinery, and equipment.

- Troubleshooting machinery and performing routine preventative maintenance.

- Reading, interpreting, and following instructions and operation manuals.

- Maintaining a schedule for inspecting, servicing, and testing machinery.

- Cleaning, repairing and installing equipment and parts as needed.

- Operating a variety of hand and power tools.

- Maintaining a clean and organized work area.

- Complying with health and safety regulations.

- Performing general maintenance work on buildings as assigned.

- High school diploma/GED.

- 2+ years of experience as a Maintenance Mechanic or in a similar role.

- Trade or vocational school graduation preferred.

- Knowledge and ability to operate hand and power tools.

- Mechanical aptitude and ability.

- Strong computer skills.

- Physical dexterity.

- Good troubleshooting skills.

- Knowledge of health and safety regulations.

Job Features

| Job Category | Manufacturing |

- Operate machinery, equipment, and computer terminals

- Test, Troubleshoot and correct panel

- Make sure wires are tie wrapped and neatly inserted in enclosures.

- Complete electrical panels on time

- Machine wiring “a huge plus”

- Visually inspect and reject parts outside of written specifications

- Effectively wire a variety of products that range from standardized design and function to non-standard products

- Operate within standard operating procedures (SOPs), position overview, wiring diagrams, schematics, blue prints, and work instructions

- Use proper tools as needed to crimp wires and create harnesses

- Complete daily production and quality logs and labor cards

- High school diploma or equivalent, with a preference for trade school training and/or 1+ years of related experience

- Experience using Electrical Schematics

- Proven electrical and mechanical aptitude

- Knowledge of Quality inspection principles

- Use of hand tools, power tools, and electrical testing equipment

- Self-starter and willing to accept new challenges

Job Features

| Job Category | Manufacturing |

- Selecting, measuring, cutting, and joining appropriate metals to specifications.

- Preparing metals and work surfaces to ensure safe and effective assemblage.

- Interpreting specifications and blueprints accurately.

- Training welding apprentices and mentoring recruits.

- Regularly cleaning and inspecting welding equipment and tools.

- Operating cranes and other machinery to transport materials to welding worksites.

- Determining correct gas ratios.

- Testing the strength of each join during and after project completion.

- Diagnosing issues and troubleshooting as required.

- Liaising with the line manager or supervisor, reporting any issues, and making suggestions for improvement.

- High school diploma or similar.

- A completed apprenticeship or vocational training.

- A relevant certificate from a welding association may be required.

- Excellent stamina, strength, and dexterity.

- Ability to remain calm and focused under pressure.

- Sound understanding of welding safety.

- The ability to teach would be advantageous.

- A willingness to learn and work overtime when required.

Job Features

| Job Category | Manufacturing |

- Answer and direct phone calls

- Organize and schedule meetings and appointments

- Maintain contact lists

- Produce and distribute correspondence memos, letters, faxes and forms

- Assist in the preparation of regularly scheduled reports

- Develop and maintain a filing system

- Order office supplies

- Book travel arrangements

- Submit and reconcile expense reports

- Provide general support to visitors

- Provide information by answering questions and requests

- Generate and handle reports

- Prepare and monitor invoices

- Carry out administrative duties such as filing, typing, copying, binding, scanning etc.

- Organize travel arrangements for senior managers

- Book conference calls, rooms, taxis, couriers, hotels etc.

- Maintain computer and manual filing systems

- Handle sensitive information in a confidential manner

- Reply to email, telephone or face to face enquiries

- Develop and update administrative systems to make them more efficient

- Resolve administrative problems

- Receive, sort and distribute the mail

- Answer telephone calls and pass them on

- Manage staff appointments

- Maintain up-to-date employee holiday records

- Coordinate repairs to office equipment

- Greet and assist visitors to the office

- Photocopy and print out documents on behalf of other colleagues

- High school diploma or equivalent. Bachelor's degree preferred.

- 4+ years supporting multiple Executive leaders

- Working knowledge of Microsoft Office Outlook, Calendar, PowerPoint, Word, and Excel. Knowledge of SharePoint and other applications a plus.

- Excellent written and verbal communication

- Excellent interpersonal skills

- Ability to apply good judgment in making independent decisions and coordinating information

- Ability to handle and manage multiple priorities and adapt to rapidly changing needs and priorities

- Organizational

- Problem solving

- Assemble machinery and components off custom blueprints

- Operate hand and power tools to fabricate parts

- Keep work station clean and organized Requirements:

- Ability to read blueprints

- Ability to operate hand and power tools

- Use a variety of precision measuring devices to set up and adjust parts and verify conformance of work

- Troubleshoot basic assembly problems.

- Perform general preventive maintenance work on tools and equipment.

- Requires high school diploma (or equivalent) plus three to five years’ related experience.

- Must be familiar with portable power tool and machine tools such as drill press, band saw, cut-off saw and grinder.

- Ability to read and understand documents such as blueprints, operating and maintenance instructions, and procedure manuals. Basic familiarity with G.D.&T. helpful but not required

- Ability to write standard documentation & comfortable with documenting on a computer

- Ability to communicate effectively (oral and written) with other employees of the organization in a quick and accurate manor.

- Requires mathematical skills that require the ability to add, subtract, multiply and divide. Must perform metric conversions.

- Ability to apply commonsense understanding to carry out instructions furnished in written, oral, or visual formats.

- Basic knowledge of carpentry and \ or pneumatics is beneficial but not require

Job Features

| Job Category | Manufacturing |

- Ability to work in a fast-paced, high-speed environment, follow standardized work and adhere to safe work practices in a continuous improvement environment

- Experience in a manufacturing environment is a plus

- Perform necessary pre-operation activities to ensure proper equipment startup and operation on multiple pieces of equipment

- Operate/monitor multiple pieces of equipment during operation to ensure quality production and minimal unplanned stops

- Communicate with team members and support teams to ensure continuous production of the correct product at high quality levels with minimal wasted time and materials

- Housekeeping and sanitation

- Assist in the progression of training and planned development of all machinists.

- Perform other duties as assigned.

- Experience as a Machine Operator

- Knowledge of Production Procedures

- Ability to Read Blueprints, Schematics and Manuals

- Analytical Skills

- Attention to Detail

- Teamwork

- Physical Stamina and Strength

- Handle Heavy Equipment

- Work Independently

- Multitask

Job Features

| Job Category | Manufacturing |

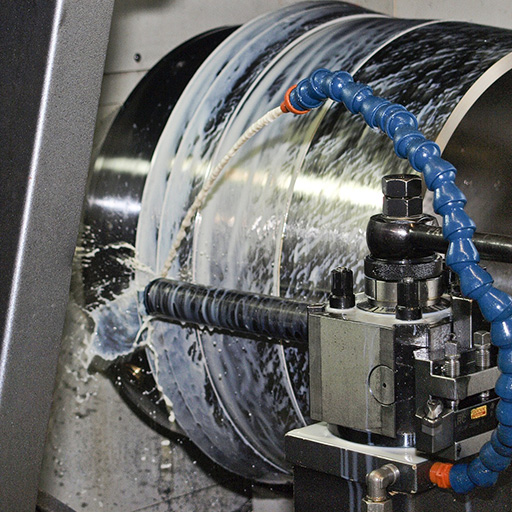

- Setup CNC turning centers for production turning.

- Troubleshoot and optimize new production programs to ensure efficient overall production.

- Document new programs and processes to ensure setups can be duplicated and overall production time is optimized.

- Oversee the quality of parts produced in the machining cell.

- To share expertise and knowledge throughout the machine shop and be a focal point for advice on machining operations

- To use skills to protect against potential damage to all machines and in particular to take overall ownership of the machine cell.

- To be proactively aware of work load and plan tooling requirements for future jobs ensuring minimum downtime.

- To make most efficient use of machinery and equipment, including the use of proper feeds and speeds.

- Inspect and deburr parts to ensure they meet blueprint specifications using proper measuring instruments.

- Produce jigs and fixtures that improve productivity.

- Implement daily and weekly maintenance programs on machine shop equipment

- Follow all safety policies and procedures.

- Assist in the progression of training and planned development of all machinists.

- Setup machines on a flexible basis to ensure optimum output throughout the shop.

- Perform other duties as assigned.

- Must have a basic understanding of CNC machining work and tool offsets.

- Must be able to identify critical blueprint dimensions and instruct workers how to inspect and check these critical dimensions.

- Ability to work on a wide variety of complex parts from drawings.

- Ability to change and adapt work behaviors based on a constantly changing production schedule.

- Must have basic computer skills including Microsoft Word, Excel, and Windows.

- Must have basic understanding of ISO 9001 and quality principles.

- Must be dependable and detailed oriented.

Job Features

| Job Category | Manufacturing |

- Set up and operate CNC Mill(s) to perform various machine functions such as; milling, turning, boring, recessing, and occasional profiling or contouring of metallic and nonmetallic work-pieces.

- Set-up, create, check programs and operate automatic numerically controlled machine tools.

- First piece and in process inspections of parts produced.

- Work from operational data to define tooling, fixturing, and machine arrangements.

- Recommend tooling arrangements, fixtures, and operational sequences, etc.

- Use a variety of precision measuring instruments.

- General knowledge of machine shop practices and techniques, machine operation and tooling.

- Must have a basic understanding and knowledge of injection molding process, equipment and materials. The addition of other molding processes is helpful.

- Completion of a state indentured tool and die apprenticeship, CNC Machinist apprenticeship or accrued experience.

- Must be able to read and understand blueprints, specifications and routings.

- Ability to add, subtract, multiply, and divide in all units of measure, using whole numbers, common fractions, and decimals.

- Minimum of 2 years experience.

- High School diploma or GED.

- Positive attitude

Job Features

| Job Category | Manufacturing |

We are looking for an energetic Warehouse Worker to receive and dispatch merchandise to and from our warehouse. The Warehouse Worker will load and unload outgoing and incoming delivery vehicles. You will select products from the warehouse, load and secure goods to pallets, move inventory to delivery area, and load merchandise. You will unload stock from delivery vehicles, and transport to and store in designated warehouse positions. You will keep your work environment clean and tidy at all times, and comply with all relevant safety rules, regulations, policies and procedures.

To ensure success you need the ability to follow instructions and operate in an orderly manner. Preferred applicants are hard-working, focused and have outstanding problem-solving skills.

Job Responsibilities:

- Ensuring cleanliness, tidiness and safety of work environment.

- Loading and unloading delivery vehicles.

- Accepting delivery of inventory.

- Counting and confirming inventory.

- Inspecting inventory for damage and faults.

- Communicating errors to relevant parties.

- Marking and labeling stock.

- Storing inventory in accessible manner.

- Loading and wrapping stock on pallets.

- Building loads with forklift and electronic pallet jack.

Job requirements:

- 18 years of age or older.

- Work experience as general laborer, preferably in warehouse.

- Ability to operate forklift proficiently.

- Completion of background investigation and drug screening.

- Strong people skills.

- Good moral character.

- Physically strong, agile and dexterous, and undeterred by heights and adverse climatic conditions.

- Positive work history and ability to maintain solid attendance.

- Available to work extended hours.

Pay Rate: $10-18 per hour

Days/Hours (shift): Monday- Friday. 1st shift (8:00am to 5:00pm), 2nd (4:30pm to 3:00am)

- Loading, unloading, shipping and receiving warehouse items.

- Transporting materials to different locations within the facility.

- Optimizing loads to ensure operational efficiency.

- Securing loads to machine before transportation.

- Inspecting for damages to vehicles.

- Scheduling vehicles for maintenance and repairs.

- Operating and managing technical equipment.

- Managing inventory by utilizing RF scanning equipment.

- Picking and wrapping orders for shipment.

- Identifying workplace safety hazards.

- Adhering to safety management standards.

- Adhering to production schedules.

- High school diploma or GED.

- Valid fork-lifting certificate.

- Excellent hand-eye coordination.

- Proficiency operating technical machinery and RF scanners.

- Good physical condition.

- Mathematical aptitude.

- Good organizational skills.

- Attention to detail.

- Good written and verbal communication.

Job Features

| Job Category | Manufacturing |

- Designing, maintaining, implementing, or improving electrical instruments, facilities, components, equipment products, or systems for industrial, commercial or domestic purposes.

- Performing a wide range of engineering tasks by operating computer-assisted design or engineering software and equipment.

- Conferring with customers, engineers, and others to discuss existing or potential engineering products or projects.

- Ensuring that installation and operations conform to standards and customer requirements by preparing electrical systems specifications, technical drawings or topographical maps.

- Establishing construction, manufacturing or installation standards or specifications by performing a wide range of detailed calculations.

- Ensuring compliance with specifications, codes, or customer requirements by directing or coordinating installation, manufacturing, construction, maintenance, documentation, support or testing activities.

- Writing reports and compiling data regarding existing and potential electrical engineering projects and studies.

- Preparing specifications for purchases of electrical equipment and materials.

- Supervising or training project team members.

- Estimating material, labor, or construction costs for budget preparation.

- Maintaining electrical equipment.

- Working with a variety of technicians.

- Bachelor degree in electrical engineering degree from an accredited school.

- Licensed as a professional engineer.

- Experience in using or a desire to learn required software.

- Knowledge of applicable codes related to electronic engineering.

- Proficient in design and calculation software.

We are currently seeking an experienced and highly-skilled Mechanical Engineer. You will collaborate with a team of engineers, architects, and designers to develop more efficient manufacturing machinery that utilizes less energy without sacrificing performance.

Job Responsibilities:

- Create, refine, and detail 2D and 3D CAD models and prepare drawings using SolidWorks.

- Analyze and detail tolerances for interference and stack – up in production situations.

- Maintain ECR/ECN and revision control documentation.

- Create and detail one-time modifications or customization to existing products.

- Communicate with internal customers to understand requirements.

- Communicate changes, special instructions and other details to the production floor.

Position requirements:

- Bachelor’ s degree in mechanical engineering, mechanical engineering technology, or a related field.

- Ability to work with customer’ s to design and develop mechanical systems and solutions for their equipment needs.

- 3+ years of experience with mechanical design or manufacturing engineering work (preferred).

- Highly proficient with Autocad software.

- Experience with mathematical computing and analysis tools knowledge such as Matlab and LabView.

- Able to create 2-D or 3-D designs to run simulations, analyze, and tests

- Monitor and analyze mechanical devices for problems.

- Develop new devices or changes to improve current equipment.

- Recommend design changes, cost reductions, warranty improvements, and manufacturing issues.

- Oversee installation of new system or machinery Perform and analyze tests to track results.

Pay Rate: $50K - 80k per year

Days/Hours (shift): Monday- Friday (8am-5pm)

The CDL Driver drives truck to transport materials to and from specified destinations. Secondary transport duties include operation of semi-roll off and van body equipment.

Job Responsibilities:

- Drives truck to destination and operates specialized pump equipment on vehicle to load, unload, or disperse cargo or materials.

- Prepares customer's delivery ticket specific to the product delivered and obtains customer signature.

- Accurate completion of electronic Driver Logs daily.

- Keeps record of materials and products transported.

- Maintains records such as vehicle logs, records of cargo, and shipping manifests according to state and federal regulations.

- Maintains telephone and electronic contact with dispatch to receive delivery instructions.

- Reads maps and follow written and verbal geographic directions.

- Inspects truck equipment and supplies such as tires, lights, brakes, gas, oil, and water.

- Secures cargo prior to and during transit.

- Ensure elite standard of all operating equipment including but not limited to inside cab, outside cab, outside tanks, hoses, trays, fittings, and all other ancillary parts.

- Other duties may be assigned.

Position requirements:

- Due to interstate travel in a commercial vehicle and federal regulations, candidates must be 21 years or older.

- Possess a Valid Class A Commercial Driver's License with HazMat and Tanker Endorsements.

- 2+ years driving experience.

- Has not received any disqualifications to drive a commercial motor vehicle according to the provisions of Federal Motor Carrier Safety Regulations, 391.15.

- Abide by standard DOT regulations at all times.

- This position requires the employee to sit and drive for long periods of time.

- Ability to read and interpret documents such as safety rules, operating and maintenance instructions, and procedure manuals.

- Must be responsible, well organized and exhibit great Safety Awareness; identify and correct conditions that effect employee and client safety. (#LI-LD1)

Pay Rate: $20K - 40K per year

Days/Hours (shift): Multiple Shifts and Hours

*Hours are subject to change depending on work load, must be flexible.

- Collecting all material and equipment to begin the process

- Reading and comprehending instructions, reading blueprints and following established procedures

- Align material and assembling parts to build more complex units

- Wrapping, banding, crating the product so it is ready for shipment.

- Moving finished products to the staging areas.

- Ability to complete multiple drive bases on a daily basis

- Cleaning and maintaining an organized work area

- Maintaining all required paperwork, records, documentation, etc.

- Recommends upgrades, repair or replacement of equipment to ensure consistent and reliable operation

- Works safely and follows all company safety rules

- Requires education equivalent to a High School Diploma.

- Requires experience in a fast-paced, team environment preferably from a manufacturing business with 1 year of mechanical assembly experience

- 1 year of experience preferred in a CNC and/or mechanic related field

- Requires the ability to be cross trained in multiple areas

- Requires the ability to read blueprints and tape measurers

- Requires working knowledge of basic hand tools

- Requires strong diagnostic skills

- Frequent use of hands to finger, handle, grasp or touch objects and tools

- Frequently is required to talk, hear and listen

- Frequent standing, walking, climbing, kneeling, squatting, stooping, crouching, crawling, twisting, bending, reaching

- Occasionally lifts and or moves up to 70 pounds

- Processing, verifying, and posting receipts for goods sold or services rendered.

- Researching and resolving account discrepancies.

- Processing and recording transactions

- Maintaining records regarding payments and account statuses.

- Obtaining information from other departments to ensure records are accurate and complete and that accounts receivable ledgers and journals are up to date.

- Working with the collections department to review accounts and client payment and credit history to develop new or better repayment terms.

- Performing administrative and clerical tasks, such as data entry, preparing invoices, sending bill reminders, filing paperwork, and contacting clients to discuss their accounts.

- Generating reports and statements for internal use.

- Engaging in ongoing educational opportunities to update job knowledge.

- Bachelor’s degree in Accounting, Finance, or related field.

- Combination of education and experience may be accepted.

- Strong math, typing, and computer skill, especially with bookkeeping software.

- Excellent communication, research, problem solving, and time management skills.

- High level of accuracy, efficiency, and accountability.

- Attention to detail.

- Ability to build relationships with clients and internal departments.